eNABLE

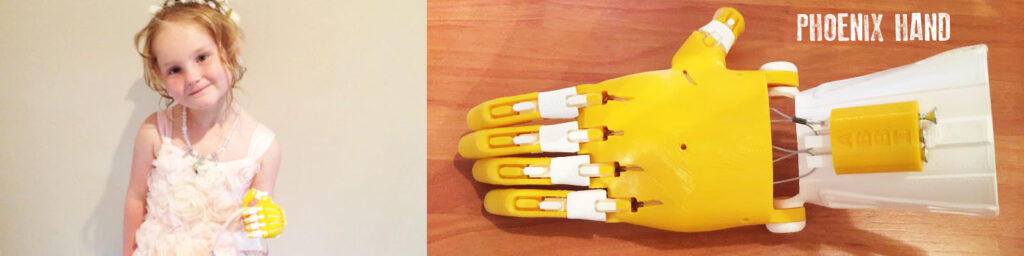

In my freshman year at WVU, I joined the Biomedical Engineering Society (BMES) chapter to help with an ongoing project. Multiple years had seen different groups try to start a chapter of a nonprofit called eNABLE, which helped to print free, upper-limb prostheses for those who need them. Especially children, who quickly outgrow any limb whether it’s $50 or $5,000.

Due to the people in my life and my experiences with them, prostheses and orthoses have always been a lingering curiosity of mine. The opportunities to work on an actual prosthesis, however, are few and far between. Thus, I was very motivated to provide my help.

The past years’ officers had been struggling to develop a group of people to manufacture and assemble a working hand that could certify the chapter to fulfill orders. Upon taking up leadership over the project, I noticed a few critical issues:

- There was a lack of knowledge about 3D-printing, sizing prostheses, and general DIY-esque tinkering.

- Even with the requisite knowledge, the printer available was old, required proprietary *everything*, and didn’t even work.

Over the course of the first year, I established a manufacturing setup and produced a limb that allowed the chapter to be certified. Then, in the following year, I developed training material and ran workshops such that each volunteer to be able to size, manufacture, and assemble any configuration of limb from scratch.

In my third year, I assisted other eNABLE chapters and volunteers around the world who were new to the organization and were looking for guidance. In anticipation for leaving on my Study Abroad, I organized the materials needed to administrate the organization to pass it on.

In my fourth year, I passed on leadership to bright, new students who had my same enthusiasm. Even after coming back from Sweden, I didn’t try to interfere with their setup and served as a reference for any volunteers with questions.